Technology

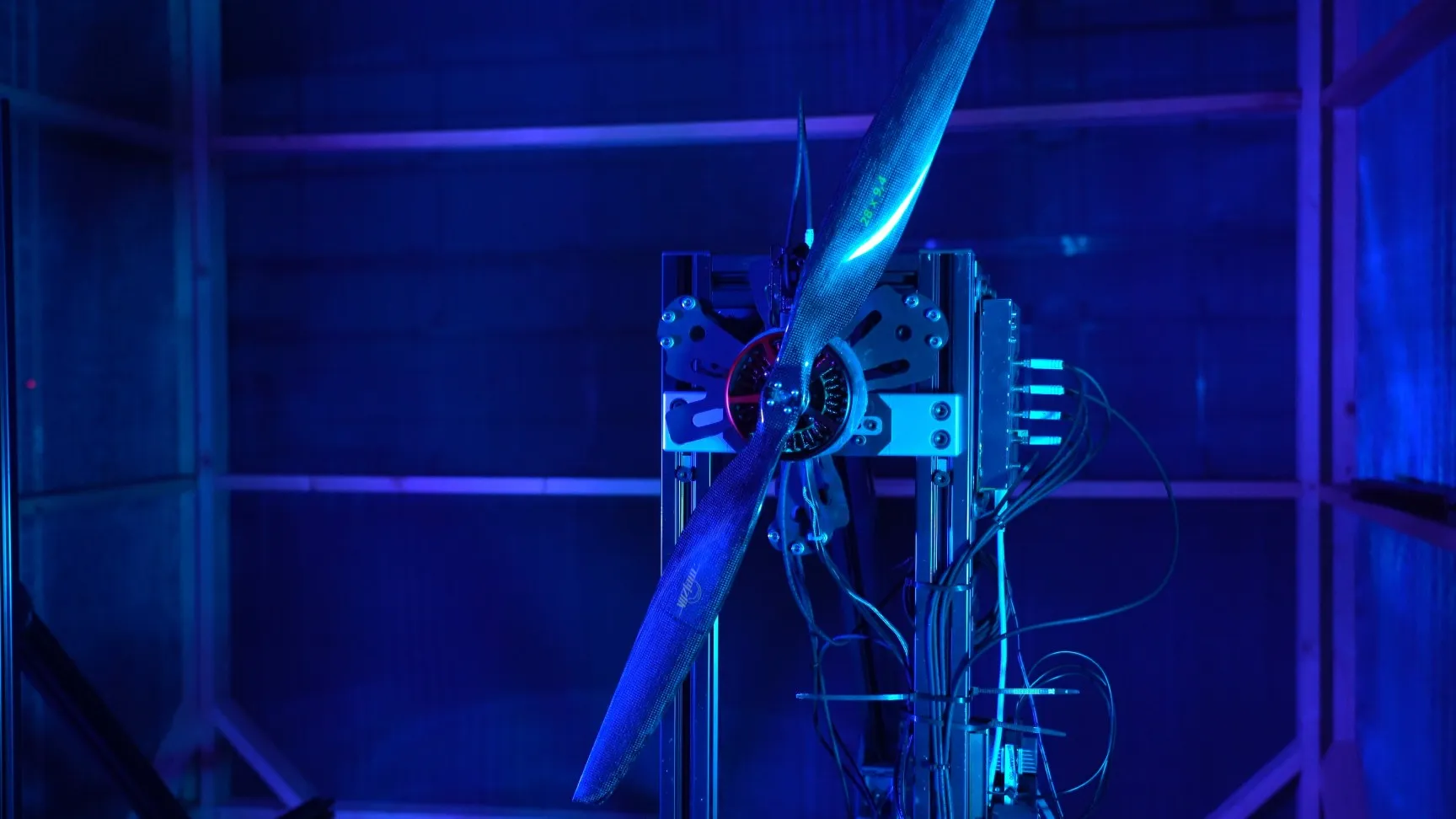

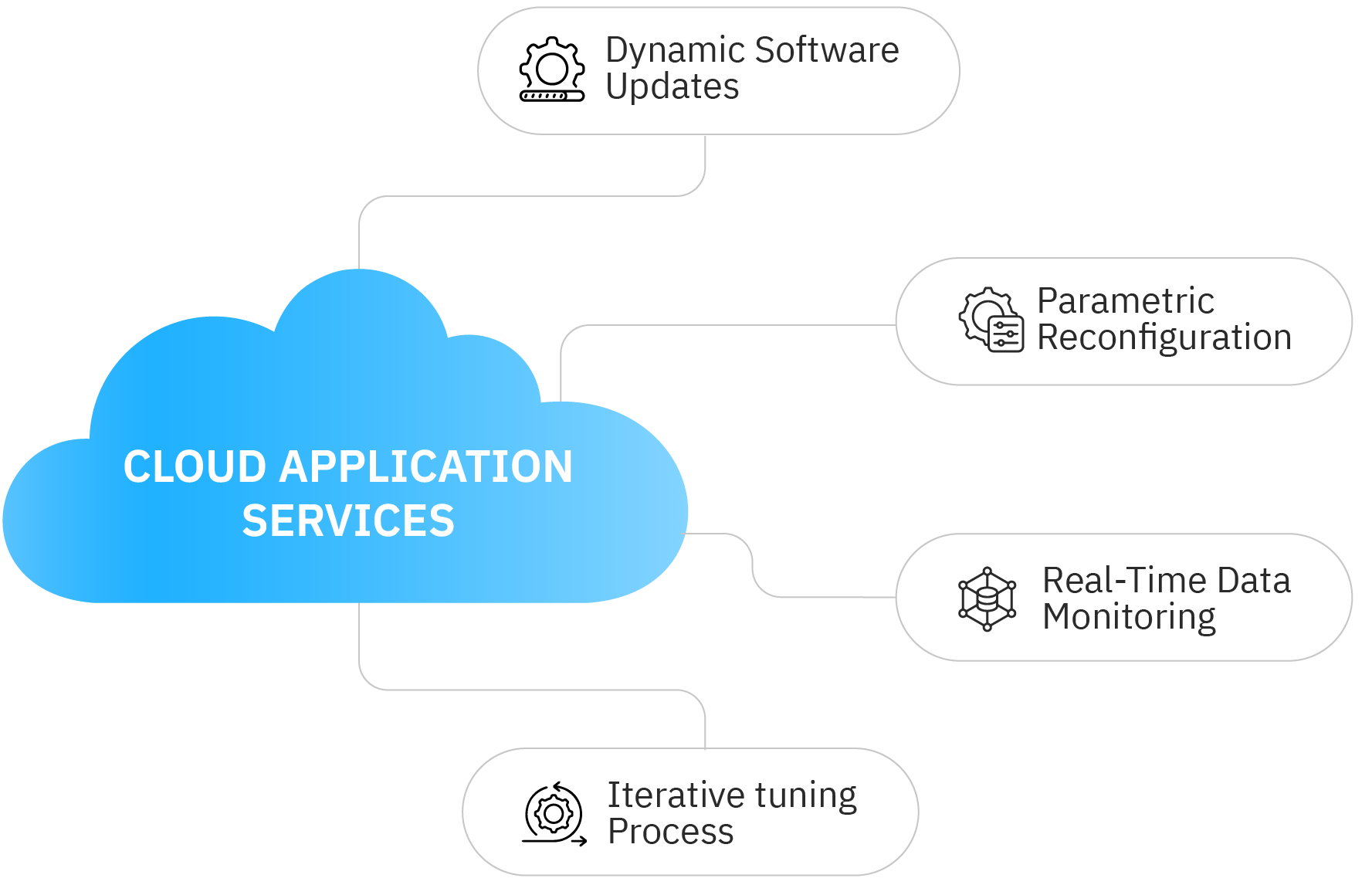

ePropelled focus on science, innovation, and invention, coupled with expertise in material science, system design, power electronics and propulsion software, positions ePropelled at the forefront of electric propulsion systems. This talent contributes to our ever-expanding disruptive portfolio of patents, ensuring our place as the leader in electric propulsion systems.

INNOVATION

Advanced technology through 55+ patents, 17 patent families.

ENERGY

Electric propulsion and power generation systems for multiple industries.

SYSTEMS

Combined product families to work together forming the best possible efficiency.